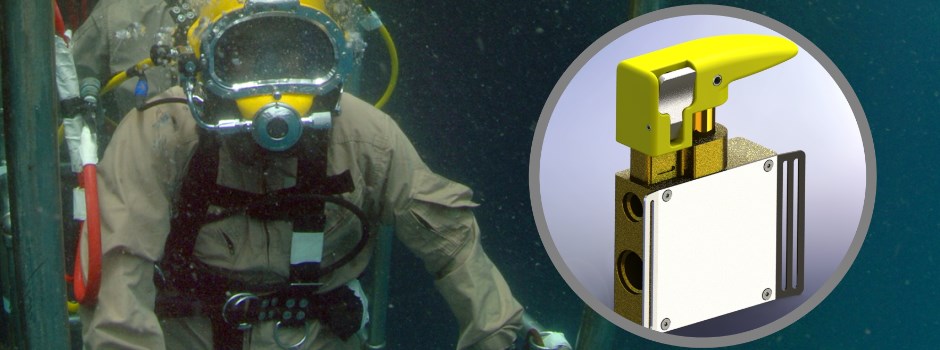

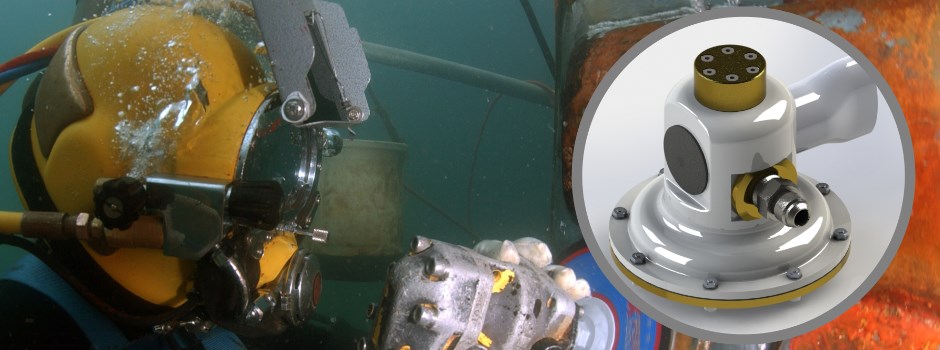

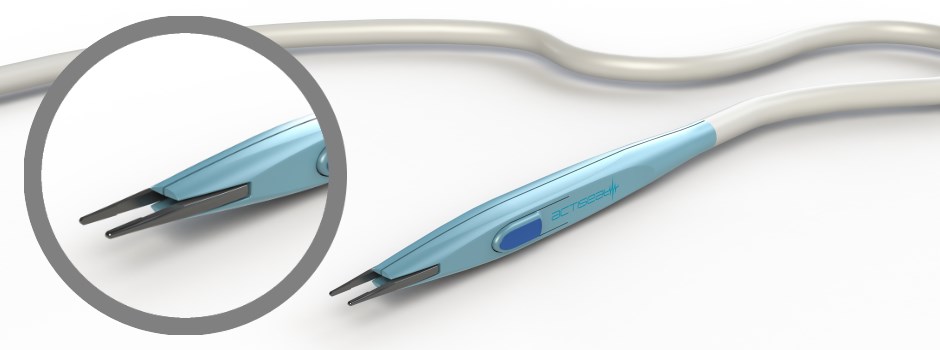

Product Design

Professional Product and Industrial design services for the customer that wants production ready designs and ingenious solutions.

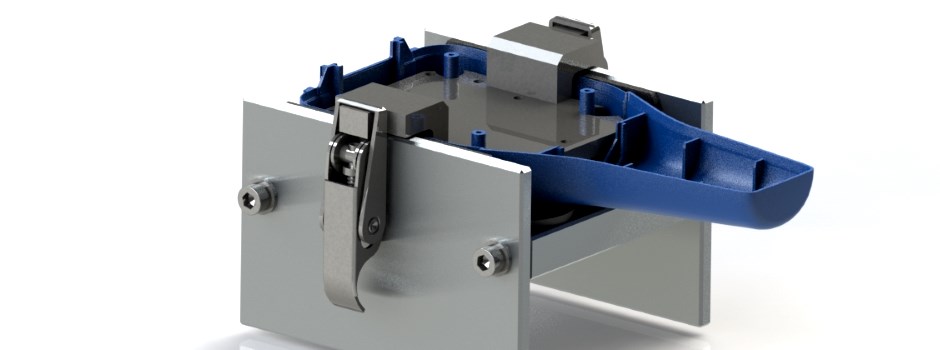

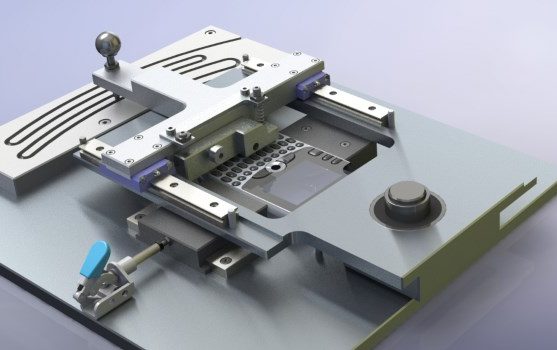

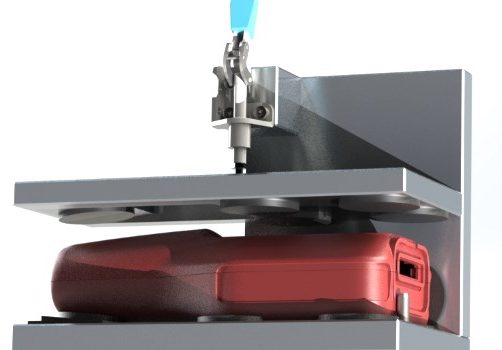

Mechanical Design

Engineering and mechanical design services from staff with diverse and extensive experience. Jigs, fixtures, special purpose machines etc.

CNC Programming

3, 4 & 5 axis CNC programming using industry leading software and expert programmers, postprocessed for your CNC machine tool.

What we do:

Alphatech has been established for over 27years. We have gathered a team of hard-working experienced designers and engineers, who can provide an excellent and cost-effective service.

Our goal is always to work with you, to ensure that the results are what you want. We will always be honest about our capabilities and the feasibility of your requirements.

What we don’t do:

- You won’t get bamboozled by technical jargon.

- We won’t take on work that we know is destined not to be practical or feasible.

- We won’t spend excessive time on fancy reports and presentations (unless you want us to!)

- You won’t get charged the exorbitant amount the large companies do. We are not the cheapest but probably the best value for money.

- You won’t wait months while we “fit you in to our schedule”.

Areas of Experience

Over 27+ years we have completed over 3000 projects, The specific sectors we have worked in are probably too numerous to list here. But this should give you an idea of the wide range of projects we have been involved with:

- Medical

- Consumer Goods

- Electronics

- Toys

- Babycare

- Plastic and die-cast moulded products.

- Composite Parts

- MOD & defence

- Agricultural vehicles

- Special purpose machinery

- Vending

- Jigs & fixtures

- Packaging

- Marine

- Vacuum formed plastic parts

- CNC machined products

- Cycles

- Kitchenware

- Rotational moulded parts

- Vehicle parts

- Motorsport

If you do not see your sector mentioned here, it doesn’t mean that we wouldn’t be interested in your project. Give us a ring or drop us and email and we can discuss your requirements.

We’ll give you an honest answer as to whether we have the knowledge and expertise to make a superb job of your product.

Recent Portfolio Items

Our Clients

Please click the button below that is most appropriate for you

TESTIMONIALS

All these testimonials are genuine comments lifted straight from customer emails without any requests or prompting.

Larry thats fantastic. To reduce the components from around 100…counting screws to now 14 moulded parts is very pleasing.

Magnificent work -you have been busy!

I didn’t mean to pressurise you to doing it over a weekend but the result is really impressive….

Many thanks for these. Apologies for not coming back to you sooner.

Your team did some great work. We were really impressed.

I would be willing to give a reference for your company any time. It will be from the experience that we have had from the excellent way that you have conducted the pick up from the previous designer.

Contact us today

Contact us today - It's free and totally without obligation.

Find out how we can help you with your project needs.